In the realm of fluid control, the ball check valve stands out as a pivotal component for ensuring efficient and reliable operation across various applications. According to John Smith, a recognized expert in fluid dynamics, "The efficacy of a ball check valve lies in its simplicity and reliability, providing a crucial function in preventing backflow in a wide range of systems." As industries increasingly prioritize efficiency and safety in fluid management, understanding the specifications and performance of top ball check valves becomes vital.

In 2023, the demand for optimal fluid control solutions necessitates a closer look at the best ball check valves available in the market. These valves not only facilitate smooth operational flow but also enhance the longevity of the systems they are integrated into. By examining the key features and advantages of the leading contenders, users can make informed decisions that align with their specific fluid control needs, ensuring operational integrity and system reliability.

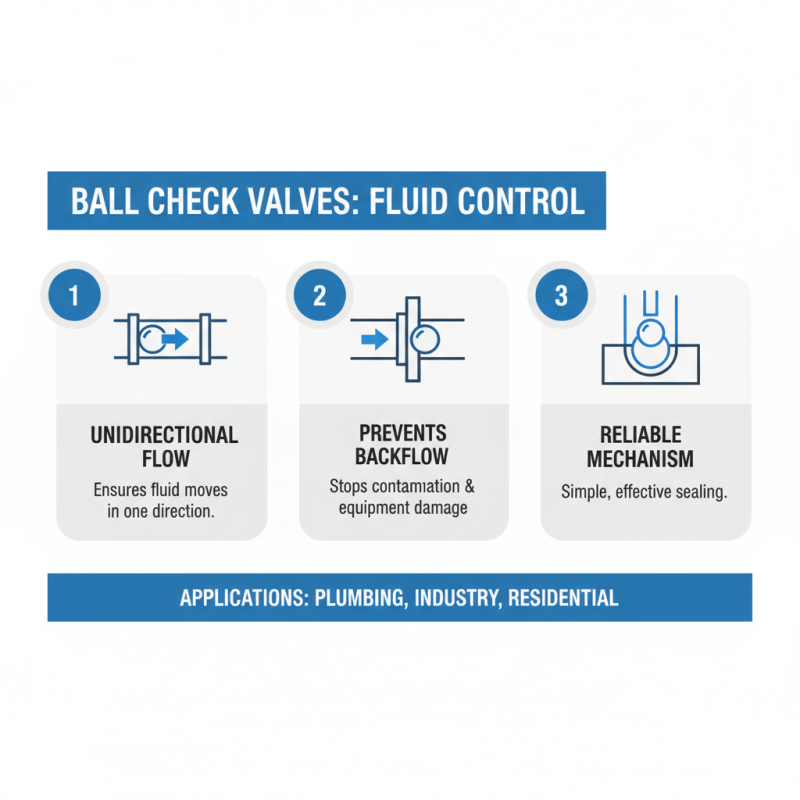

When it comes to ensuring optimal fluid control in various applications, choosing the right ball check valve is essential. These valves are designed to allow fluid to flow in one direction while preventing backflow, making them crucial in systems where maintaining pressure and preventing contamination is a priority. In 2023, several models have emerged as top contenders, offering durability, efficiency, and ease of installation, making them suitable for both residential and industrial applications.

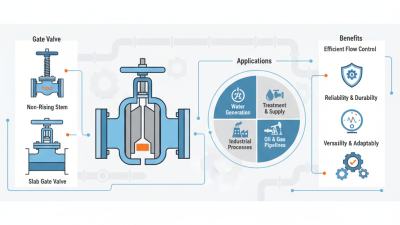

When selecting a ball check valve, consider the material from which it is made. Valves come in a variety of materials, including PVC, brass, and stainless steel, each offering different advantages depending on the fluid type and operating conditions. Additionally, the valve size and flow rate capacity should match the requirements of your system to ensure optimal performance.

Tips: Always check the valve’s specifications for pressure ratings and compatibility with the fluids you'll be using. Regular maintenance, such as cleaning and inspection, can extend the life of your valve and prevent unexpected failures. Lastly, if you’re uncertain about installation or compatibility, consulting with a professional can help you make the best decision for your specific application, ensuring you reap the full benefits of advanced fluid control technologies.

Ball check valves play a critical role in fluid control systems by ensuring that fluids flow in a single direction while preventing backflow. This is essential in various applications, from plumbing to industrial machinery, as backflow can cause contamination, equipment damage, and inefficiencies in the system. By utilizing the inherent design of a ball mechanism, these valves provide reliable sealing and effective operation, making them a popular choice in both commercial and residential applications.

When selecting a ball check valve, it’s important to consider factors such as the fluid’s temperature, pressure, and chemical composition. Ensuring compatibility with the system can prevent leaks and failures. Additionally, regular maintenance can prolong the life of the valves; inspecting for signs of wear and tear will help in identifying potential issues early.

Tips:

1. Always consult technical specifications to match the valve with your system’s needs.

2. Consider installing inline strainers to reduce the risk of debris accumulation, which can affect valve performance.

3. Periodic testing of the valve functionality can help maintain optimal operation and prevent unexpected failures in fluid systems.

When selecting a ball check valve, several key features should be considered to ensure optimal fluid control. One crucial aspect is the valve's material composition. Common materials include brass, stainless steel, and PVC, each offering different levels of resistance to corrosion and temperature variations. According to industry reports, stainless steel valves are preferred for applications involving harsh chemicals due to their durability and resistance to pitting and stress corrosion cracking.

Another important feature is the valve's size and connection type. Proper sizing ensures that the valve can handle the required flow rate without causing pressure drops that can impair system performance. The connection type, whether threaded, flanged, or welded, should be compatible with the existing system to avoid leaks and installation issues. Reports indicate that improper sizing or incompatible connections can lead to significant downtime and additional costs in industrial applications.

**Tips:** When assessing a ball check valve for your project, consider conducting a pressure-testing phase post-installation to identify any potential weak points. Additionally, consult fluid flow simulations for a precise understanding of how different valve sizes may impact overall system efficiency.

This chart provides a comparison of key features of the top 5 ball check valves based on flow rate, pressure rating, and durability.

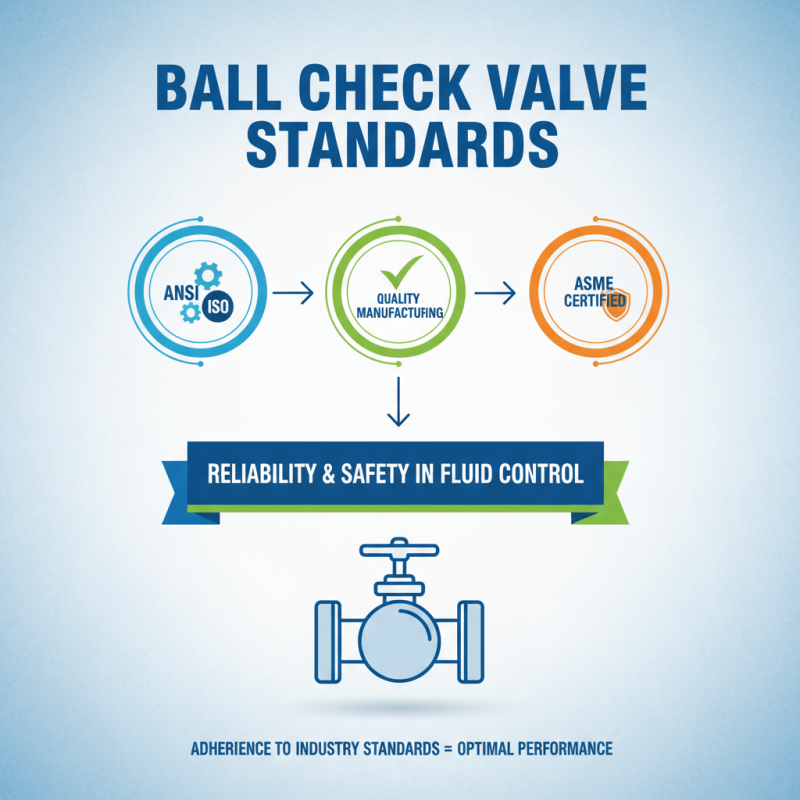

When selecting ball check valves for fluid control, adherence to industry standards and certifications is paramount to ensure reliability and safety. These standards often include guidelines set by organizations such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO). Compliance with these standards ensures that the valves are manufactured to specific quality levels, guaranteeing their performance under various operational conditions. Moreover, certifications such as those from the American Society of Mechanical Engineers (ASME) further validate that the products meet stringent safety and quality benchmarks.

In addition to these certifications, attention to material standards is crucial for fluid control applications. The use of materials that comply with the relevant ASTM specifications not only enhances the durability of the ball check valves but also mitigates risks associated with hydraulic failures. This commitment to quality assurance provides users with confidence in the performance of their fluid control systems, ensuring that the valves will function effectively over time, even under demanding conditions. Adopting these industry practices not only contributes to operational efficiency but also emphasizes the importance of safety and environmental responsibility in fluid management systems.

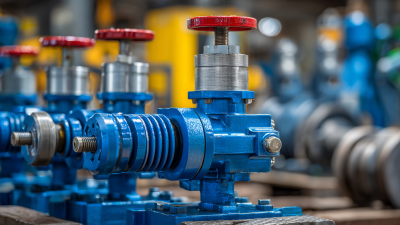

In 2023, the market for ball check valves has expanded, with numerous brands offering innovative designs and features that cater to varying fluid control needs. This comparative analysis highlights the key attributes that distinguish the leading brands in the industry. One critical factor is the material composition of the valves, as different applications may require anti-corrosive materials or high-pressure tolerance. Brands that utilize advanced polymers or high-grade metals typically offer enhanced durability and resistance to harsh environments.

Additionally, the design efficiency of ball check valves plays a significant role in their performance. Some brands emphasize streamlined designs that minimize fluid turbulence and pressure drop, allowing for improved flow rates and reduced energy consumption. Furthermore, user-friendly features such as easy installation, maintenance accessibility, and compatibility with a range of piping systems set top-performing brands apart from their competitors.

By analyzing these factors, users can make an informed decision regarding which ball check valve best suits their specific operational requirements and enhances overall system efficiency.

In 2023, the selection of the best ball check valves is crucial for achieving optimal fluid control in various applications. Ball check valves play a significant role in preventing backflow, ensuring the efficiency and safety of fluid systems. When choosing a ball check valve, key features to consider include material durability, pressure rating, and ease of maintenance, all of which directly impact performance and reliability.

Industry standards and certifications are essential for assuring the quality of ball check valves, as they provide guidelines that ensure products meet safety and performance benchmarks. A comparative analysis of leading brands reveals significant differences in design and functionality, emphasizing the importance of selecting the right valve for specific needs. Real-world applications demonstrate the effectiveness of ball check valves in various settings, highlighting their impact on operational performance and fluid management strategies.

Accreditations

ISO 9001 Quality Management

HSE Management Compliant

Products and services comply with relevant Australian (AS) and international (ISO, etc.) Standards.

"*" indicates required fields