Choosing the right water control valve is crucial for many applications. The right valve ensures efficient water flow and management. However, this task can be complex and overwhelming.

Understanding your specific needs is essential. Different situations require different types of water control valves. For instance, irrigation systems rely on valves that manage flow differently than household plumbing. You might wonder which valve fits your requirements best. Each valve type has its pros and cons, which can complicate your decision.

Consider factors like size, pressure, and application. A valve that works well for one environment may falter in another. You may make mistakes if you rush the process. Be willing to reflect on your choices and reassess your priorities. Ultimately, the goal is to find a water control valve that perfectly suits your needs.

Water control valves play a crucial role in managing fluid flow. Understanding their basics can help you choose the right type for your needs. These valves come in various designs, each suited for different applications. For example, a ball valve is excellent for quick shut-off. Meanwhile, a globe valve offers better throttling capability. Knowing these characteristics will guide your decision-making.

When selecting a valve, consider the flow requirements. Think about pressure, temperature, and flow rate. You might need a valve that can withstand high pressure, or perhaps one that operates effectively in extreme temperatures. It’s essential to match the valve's specifications with your system's demands. Sometimes, buyers overlook these details, leading to inefficiencies.

Additionally, installation space is a significant factor. Measure your available area carefully. Some valves are bulkier than others, making them harder to fit into tight spots. Checking compatibility with existing piping is also vital. A mismatch can lead to leaks or operational failures. Reflecting on these aspects can save you time and resources down the line.

When selecting a water control valve, it's essential to pinpoint your specific needs. Start by identifying the application. Do you need a valve for irrigation, industrial processes, or plumbing? Each application has unique requirements. For instance, irrigation valves should handle diverse water flows, while industrial valves may face higher pressure levels.

Consider the type of fluid. Are you managing clean water or contaminated liquids? Different materials and designs suit various fluids. You may overlook this detail, but it significantly affects the valve's longevity. Think about the environment where the valve will be installed. Will it experience extreme temperatures or corrosive conditions? Assessing these factors helps ensure optimal performance.

Don’t forget about sizing. A valve too large or small can cause problems. It’s a common oversight many make. Also, think about the ease of maintenance. Some valves are easier to service than others. Check the accessibility and design, as this affects long-term use. Reflecting on these details will guide you toward a more informed choice.

This chart illustrates the comparison of different types of water control valves based on their applications and efficiency ratings.

When evaluating different types of water control valves, it's crucial to understand their specific functions. Ball valves offer excellent sealing capabilities and are easy to operate. They are perfect for quick shut-off. On the other hand, gate valves are best for full flow applications but can be tricky to manipulate in tight spaces.

Tips: Consider the size of your plumbing system. Proper sizing can prevent leaks and ensure efficient operation. If the valve doesn’t fit right, problems will arise. Also, think about the material. Stainless steel and PVC have different durability levels. Choose one based on your environmental conditions.

It's essential to assess future needs as well. Some valves are easier to upgrade than others. For example, pitot valves allow for flow measurements, which could be beneficial later. However, installing them might require expertise. So, it’s okay to ask for help if needed. Not all options are user-friendly, and navigating choices can sometimes be overwhelming.

| Valve Type | Application | Material | Pressure Rating | Typical Uses |

|---|---|---|---|---|

| Gate Valve | On/Off Control | Cast Iron, Stainless Steel | 150-300 psi | Water Supply, Irrigation |

| Globe Valve | Flow Regulation | Bronze, PVC | 150-600 psi | Cooling Systems, Water Treatment |

| Ball Valve | Quick Shutoff | Brass, PVC | 150-300 psi | Plumbing, Gas Supply |

| Check Valve | Prevent Backflow | PVC, Metal | 50-150 psi | Pumps, Water Lines |

| Solenoid Valve | Automated Control | Plastic, Brass | 10-150 psi | Irrigation Systems, Industrial Applications |

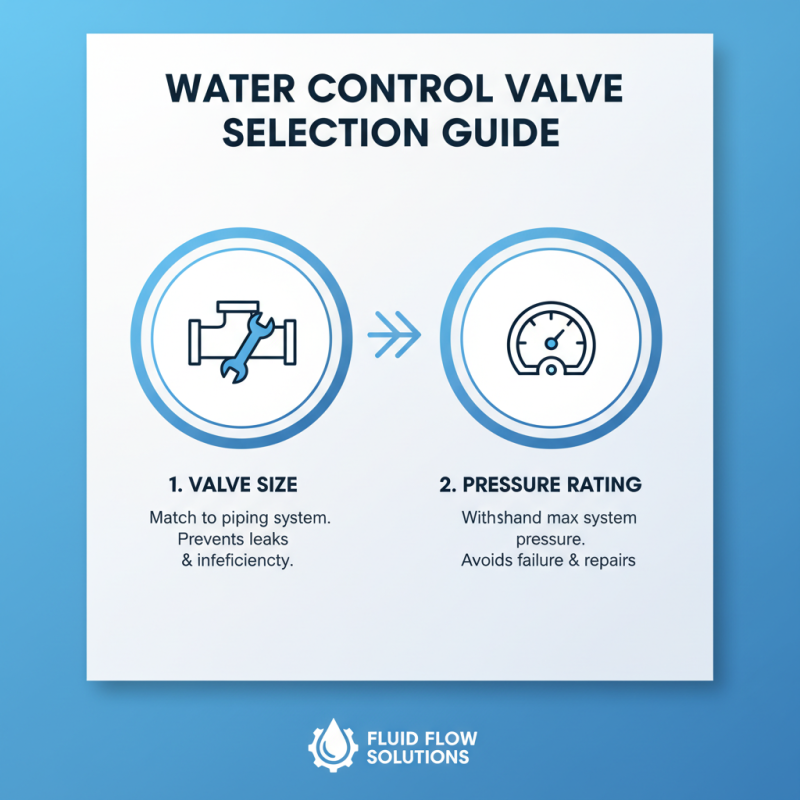

When selecting a water control valve, several key features deserve attention. The size of the valve is crucial. It must align with your piping system. An ill-fitting valve can lead to leaks or inefficient operation. Additionally, consider the pressure rating. It should accommodate the maximum pressure in your system. A valve rated too low may fail, resulting in costly repairs.

Material choice is another important aspect. Different environments require specific materials. For example, stainless steel is great for corrosion resistance. Plastic valves might suffice in less demanding applications. However, make sure to reflect on the longevity of your choice. A valve that deteriorates quickly can disrupt your operations.

Don’t forget about ease of operation. Some valves come with manual controls, while others feature automation. Your decision should reflect your specific needs. Think about the future too. Will the technology or system you choose still be relevant in a few years? It’s a complex choice, but pondering these aspects will lead you to a better decision.

When installing water control valves, precision is key. Start by turning off the water supply to prevent leaks. Choose a location that allows easy access for future maintenance. You might think it’s simple, but overlooking the right placement can cause headaches later.

Maintenance is just as vital. Regularly check for leaks and corrosion. Clean the valves periodically to ensure proper functionality. These simple actions can extend the life of your valve significantly. Don't ignore the small signs, like a slight drip. It could signal a bigger problem down the line.

Here are some essential tips: Always use the right tools for installation. Misusing tools can damage the valves. Consider the water pressure in your system. High pressure may require additional components. Monitoring your system regularly helps catch issues early. Stay proactive with maintenance to save time and money.

Accreditations

ISO 9001 Quality Management

HSE Management Compliant

Products and services comply with relevant Australian (AS) and international (ISO, etc.) Standards.

"*" indicates required fields