In the realm of fluid control systems, the significance of flow valves cannot be overstated. As per a report from the

Fluid Control Industry Alliance, implementing advanced flow valve technology has shown a remarkable potential to boost efficiency by up to 30%, significantly optimizing the energy consumption and operational performance of various industrial systems.

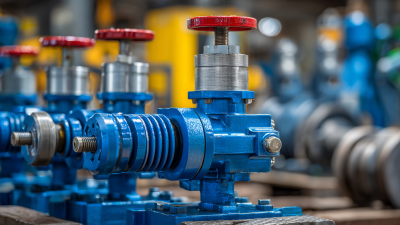

Flow valves serve as crucial components in regulating the flow rate and pressure of fluids, allowing for precise control that is essential in applications ranging from chemical processing to water treatment facilities.

The integration of smart flow valve solutions not only enhances control but also contributes to substantial cost savings and sustainability goals.

As industries strive towards more efficient and eco-friendly operations, understanding the functionality and benefits of flow valves becomes imperative for engineers and decision-makers alike.

In the realm of fluid control systems, the significance of flow valves cannot be overstated. As per a report from the

Fluid Control Industry Alliance, implementing advanced flow valve technology has shown a remarkable potential to boost efficiency by up to 30%, significantly optimizing the energy consumption and operational performance of various industrial systems.

Flow valves serve as crucial components in regulating the flow rate and pressure of fluids, allowing for precise control that is essential in applications ranging from chemical processing to water treatment facilities.

The integration of smart flow valve solutions not only enhances control but also contributes to substantial cost savings and sustainability goals.

As industries strive towards more efficient and eco-friendly operations, understanding the functionality and benefits of flow valves becomes imperative for engineers and decision-makers alike.

Flow valves are essential components in fluid control systems, designed to regulate the flow of liquids and gases. By adjusting the path of the fluid, these valves ensure optimal performance in various applications, from industrial processes to residential plumbing. Understanding the types of flow valves is crucial for selecting the right one for a specific system. The most common types include globe valves, ball valves, and gate valves, each with unique mechanisms that influence their efficiency and effectiveness.

Globe valves are designed for precise flow control, making them ideal for applications that require throttling. Ball valves, on the other hand, offer quick shut-off capabilities and low resistance to flow, which makes them suitable for on/off applications. Gate valves provide a straight-line flow path and are primarily used for fully open or fully closed operations. Each type plays a significant role in enhancing fluid control, contributing to an overall efficiency improvement of up to 30 percent in many systems. By understanding these differences, engineers and operators can make informed decisions to optimize their operations.

Flow valves play a crucial role in fluid control systems, enhancing efficiency through various advanced features. One of the key characteristics is their ability to provide precise control over flow rates. This is achieved through innovative design elements such as adjustable orifice sizes and specialized flow path configurations. By allowing for optimal flow management, these valves can significantly reduce energy consumption and operational costs, leading to approximately a 30 percent improvement in efficiency.

Another important feature is the integration of smart technologies, such as sensors and automated controls. These advancements enable real-time monitoring and rapid adjustments to flow conditions, ensuring that systems operate at peak performance. Additionally, flow valves with advanced sealing mechanisms minimize leakage, which further contributes to overall efficiency. Their durable construction and resistance to wear and corrosion also result in lower maintenance needs and longer service life, making them a smart investment for any fluid control application.

Flow valves play a crucial role in optimizing fluid control systems across various industries. Recent reports indicate that implementing advanced flow valve technology can lead to a staggering 30 percent improvement in efficiency. This enhancement is largely attributed to the valve's ability to precisely regulate fluid flow, minimizing waste and energy consumption. According to a study by the Hydraulic Institute, systems utilizing modern flow valves can reduce operational costs significantly by cutting down the energy required for fluid movement.

Moreover, the quantification of this 30 percent efficiency improvement hinges on the valve’s design, material, and control mechanisms. A report by the American Society of Mechanical Engineers notes that properly calibrated flow valves not only ensure optimal pressure and flow rates but also prolong equipment lifespan due to reduced wear and tear. In industrial applications, this means that companies can expect lower maintenance costs and less downtime, translating into higher productivity and profitability. The integration of smart technologies in flow valves further amplifies these benefits by allowing for real-time monitoring and adjustments based on system demands.

Flow valves play a crucial role in various industries by regulating fluid movement with precision and efficiency. In the chemical manufacturing sector, flow valves can improve process reliability, resulting in a reported efficiency enhancement of up to 30%. This optimization not only helps in maintaining optimal fluid flow but also minimizes wastage and operational costs. According to a report by the International Society of Automation, the implementation of advanced flow valves in chemical plants has led to a decrease in energy consumption by approximately 20%, making it a cost-effective choice for industry leaders.

In the water management industry, flow valves are essential for controlling water distribution systems. Their ability to adjust the flow rates based on real-time demand helps in reducing water loss, with studies indicating a potential reduction of up to 15% in wastage. Additionally, in the food and beverage sector, precise control over fluid flow is critical for maintaining quality and safety standards. The use of smart flow valves has demonstrated improvements in compliance with safety regulations by nearly 25%, showcasing their importance across multiple applications.

**Tips:** Regular maintenance of flow valves is essential for optimal performance. Ensure that valves are regularly inspected for wear and tear, and replace any outdated parts to maintain efficiency. Implementing smart monitoring systems can also provide real-time data, allowing for proactive adjustments and minimizing downtime.

| Industry | Application | Efficiency Improvement (%) | Flow Control Type |

|---|---|---|---|

| Chemical Processing | Material Mixing | 35 | Pressure Control |

| Water Treatment | Filtration | 30 | Flow Regulation |

| Oil & Gas | Flow Measurement | 28 | Volume Control |

| Pharmaceuticals | Dosing Processes | 32 | Flow Metering |

| HVAC | Heating Control | 33 | Temperature Regulation |

The landscape of flow valve technology is rapidly evolving, driven by the increasing demands for efficiency and precision in fluid control. Emerging technologies in the field are expected to enhance the capabilities of flow valves, providing significant improvements in performance. According to a report by MarketsandMarkets, the global flow control market is projected to grow from USD 30.82 billion in 2021 to USD 43.18 billion by 2026, at a CAGR of 7.0%. Innovations such as smart flow valves, integrated with IoT and AI capabilities, are poised to play a crucial role in this growth by allowing operators to monitor and control fluid dynamics in real-time, leading to optimized processes and reduced operational costs.

Additionally, the shift towards sustainability is pushing the boundaries of flow valve design and functionality. The adoption of environmentally friendly materials and energy-efficient designs is becoming more prevalent. A study by the International Energy Agency indicated that improving fluid control systems could lead to energy savings of up to 30% across various industries. This statistic underscores the importance of investing in new flow valve technologies that not only enhance efficiency but also contribute to overall sustainability efforts in the industrial sector. As these trends continue to unfold, the future of flow valve technology promises to deliver smarter, more efficient, and eco-friendly solutions for fluid control challenges.

Accreditations

ISO 9001 Quality Management

HSE Management Compliant

Products and services comply with relevant Australian (AS) and international (ISO, etc.) Standards.

"*" indicates required fields