A hydraulic valve is a crucial component in hydraulic systems. It controls the flow and direction of hydraulic fluid. Understanding how a hydraulic valve works can enhance system efficiency. The valve regulates fluid pressure and fluid flow, ensuring machinery operates smoothly.

In essence, these valves are the brain of hydraulic circuits. They can be manual or automatic. In manual systems, an operator adjusts the valve position. Automatic valves respond to pressure or flow changes. This adaptability improves system responsiveness but may create complications.

Hydraulic valves come in various types, such as relief, check, and directional control valves. Each type serves a unique purpose. However, misusing a hydraulic valve can lead to system failure. It's vital to ensure proper installation and maintenance. Recognizing their importance can prevent costly mistakes in hydraulic applications.

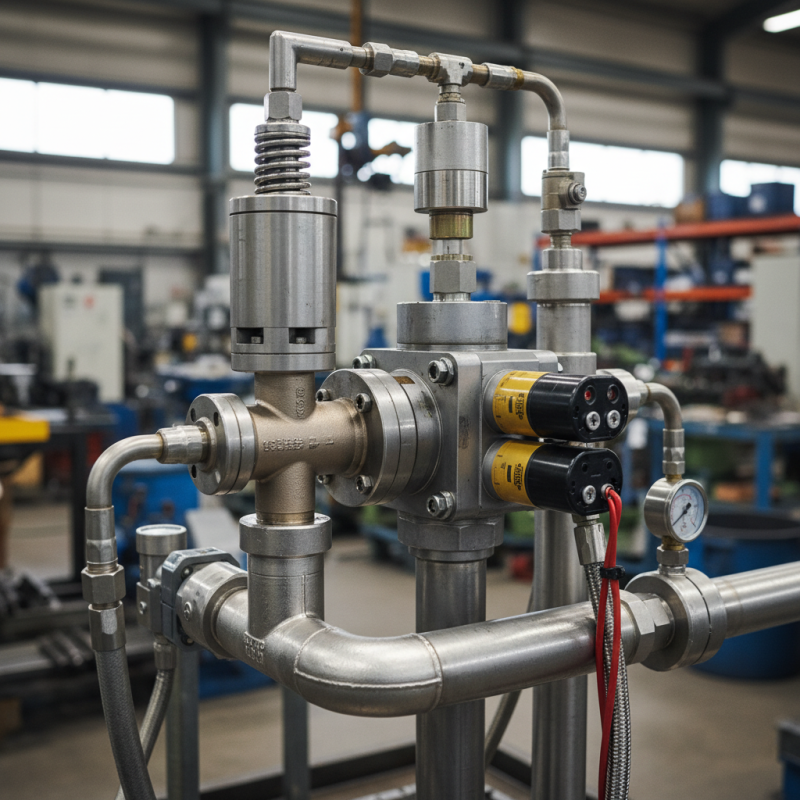

A hydraulic valve plays a crucial role in hydraulic systems. It controls the flow and pressure of fluids. These valves can regulate the energy that flows through various machinery. Hydraulic valves can be found in construction equipment, automotive systems, and manufacturing tools.

Hydraulic valves are designed to direct fluid in a controlled manner. They can be manually operated or automated. According to industry reports, about 40% of hydraulic system failures are linked to valve issues. This highlights the importance of regular maintenance and inspection.

Tips: Always monitor fluid levels in the system. Check for leaks around the hydraulic valve.

Understanding the types of hydraulic valves is essential. There are two main types: directional control valves and pressure control valves. Directional control valves dictate the path of the fluid. Pressure control valves manage the system's pressure levels. Misunderstanding these functions can lead to inefficiencies. Over time, improper use can cause significant wear on the machinery. Regular training for operators is often overlooked but critical for performance.

| Dimension | Description | Function | Operating Principle |

|---|---|---|---|

| Pressure Rating | The maximum pressure the valve can withstand. | Regulates the flow and pressure of hydraulic fluids. | Operates based on the pressurized fluid acting on the valve seat. |

| Flow Rate | The volume of fluid that can pass through the valve per unit of time. | Controls the speed and force of hydraulic actuators. | Determined by the size of the valve opening and the pressure difference. |

| Type | Various types such as directional, pressure, and flow control valves. | Directs or regulates the hydraulic fluid flow. | Uses mechanical actuators or electronic controls for operation. |

| Construction Material | Common materials include steel, aluminum, and plastic. | Ensures durability and resistance to corrosion and wear. | Depends on the application and required pressure ratings. |

| Actuation Method | Can be manual, pneumatic, or electric. | Enables control of the valve opening and closing. | Based on the source of energy provided for actuation. |

Hydraulic valves play a crucial role in fluid control within hydraulic systems. Understanding their basic components can help demystify their operation. At the core of a hydraulic valve is the spool. This cylindrical piece moves back and forth within a housing. It directs fluid flow to different parts of the system. The spool's position determines the valve's function. If it sticks, the entire system can malfunction.

Another vital component is the actuator. It can be electric, pneumatic, or hydraulic itself. The actuator controls the spool's movement based on signals it receives. A faulty actuator can lead to erratic valve behavior. Regular checks are essential to prevent this.

Lastly, the seals and springs within the valve ensure proper operation. Seals prevent leaks, while springs return the spool to its neutral position. However, these components wear out over time. Neglecting maintenance can lead to inefficient operation. Regular inspections and timely replacements of these parts improve reliability.

Hydraulic valves play a vital role in controlling fluid flow in hydraulic systems. They manage pressure and direct the flow of hydraulic fluid precisely. The efficiency of these valves significantly impacts the overall performance of machinery. According to industry reports, the global hydraulic valve market is projected to reach approximately $5 billion by 2025, growing at a CAGR of about 6.5%. This growth underscores the increasing reliance on hydraulic systems across various sectors, including manufacturing and automotive.

A fundamental function of hydraulic valves is to regulate fluid movement. They can open, close, or restrict flow based on system requirements. Common types include directional control valves and pressure relief valves. These devices ensure that systems operate smoothly, preventing overload and maintaining safety. It's crucial to understand that improper valve selection can lead to inefficiencies and mechanical failures. The wrong valve can cause excessive pressure buildup, ultimately leading to system failure.

Tip: Regularly inspect hydraulic systems to identify potential issues. Simple checks can prevent costly repairs. Keep in mind that wear and tear in valves can lead to leaks or malfunctions. Staying proactive about maintenance can extend the lifespan of hydraulic components. Always refer to technical specifications to ensure compatibility. Understanding the nuances of hydraulic valves is essential for anyone working with fluid power systems.

Hydraulic valves play a crucial role in controlling fluid flow in hydraulic systems. They come in various types, each tailored for specific applications. For instance, directional control valves manage the path of fluid, allowing or blocking flow in certain directions. These valves are essential in machinery where precise movement is necessary.

Pressure relief valves ensure the system does not exceed safe pressure levels. They are vital in preventing equipment damage. Moreover, flow control valves regulate the speed of hydraulic actuators. This parameter influences the performance of machines significantly. Each valve type has its unique challenges, like wear and tear over time or the risk of leaking seals.

Understanding the right valve for your application can be tricky. Misjudgments can lead to inefficiencies or system failures. Not all systems require the same type of valve. It’s essential to evaluate system needs carefully. Adopting a trial-and-error approach might yield better results in some cases. Sometimes, even basic adjustments can lead to improved efficiency and performance.

This chart illustrates the different types of hydraulic valves and their common applications in various industries.

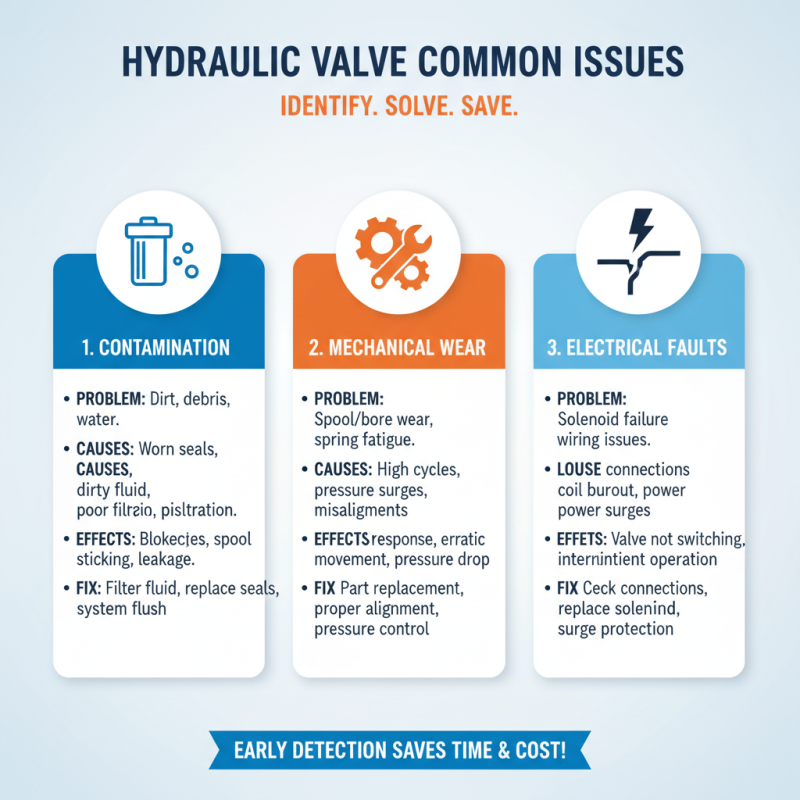

Hydraulic valves play a crucial role in controlling fluid flow in hydraulic systems. However, they can encounter common issues that may hinder their performance. Identifying these problems early can save time and maintenance costs.

One common issue is contamination. Dirt and debris can clog the valve, causing it to malfunction. Regularly inspect the hydraulic fluid for impurities. Changing the fluid regularly helps maintain valve efficiency.

Another problem is leakage. It can occur at seals or connections. If you notice fluid pooling under the system, check for worn seals. Tightening connections may also help.

Tips for maintenance include keeping the environment clear of contaminants. Regularly monitor the system's pressure levels. Address any unusual noises promptly. These steps help ensure that your hydraulic valves work effectively and efficiently.

Accreditations

ISO 9001 Quality Management

HSE Management Compliant

Products and services comply with relevant Australian (AS) and international (ISO, etc.) Standards.

"*" indicates required fields