In today's rapidly evolving industrial landscape, the significance of pneumatic valves cannot be overstated. As automation systems become increasingly sophisticated, these components play a crucial role in ensuring efficiency, reliability, and performance. According to Dr. Emily Thompson, a leading expert in fluid power systems, "Pneumatic valves are the backbone of modern automation, enabling precise control over air and fluid movements that drive operational success." Her insights underscore the necessity of understanding how pneumatic valves function and their application in various automated processes.

In today's rapidly evolving industrial landscape, the significance of pneumatic valves cannot be overstated. As automation systems become increasingly sophisticated, these components play a crucial role in ensuring efficiency, reliability, and performance. According to Dr. Emily Thompson, a leading expert in fluid power systems, "Pneumatic valves are the backbone of modern automation, enabling precise control over air and fluid movements that drive operational success." Her insights underscore the necessity of understanding how pneumatic valves function and their application in various automated processes.

The integration of pneumatic valves into automation systems not only enhances operational efficiency but also contributes to safety and cost-effectiveness. With advancements in technology, the design and functionality of pneumatic valves have evolved, allowing for better performance and adaptability in diverse industrial environments. This article will explore the top five reasons why pneumatic valves are indispensable in contemporary automation, highlighting their versatility, reliability, ease of maintenance, and overall importance in streamlining industrial operations. Through an in-depth analysis, we aim to illustrate how these components serve as critical enablers of automation, reinforcing Dr. Thompson's assertion of their foundational status in the industry.

Pneumatic valves play a crucial role in modern automation systems, significantly enhancing operational efficiency across various industries. According to a report by the International Society of Automation, the integration of pneumatic systems can increase productivity by up to 30% when replacing mechanical systems. This efficiency stems from the rapid response times and the precise control pneumatic valves offer, enabling automated processes to operate smoothly and reliably.

To optimize the use of pneumatic valves, manufacturers should consider implementing regular maintenance schedules. This includes checking for air leaks, ensuring proper alignment, and verifying that the valves are functioning within their specified pressure ranges. Additionally, investing in high-quality valves can yield significant long-term savings, as they typically have lower failure rates and longer service lives, as noted in a research study by the Fluid Power Journal, which reported that durable valves reduce operational downtime by an average of 25%.

In selecting pneumatic valves, automation engineers should also focus on compatibility with existing systems and the specific requirements of their applications. Utilizing data from a recent market analysis by Allied Market Research, companies can make informed decisions that enhance automation efficiency and overall productivity. By prioritizing these factors, businesses can harness the full potential of pneumatic valves in their automation strategies.

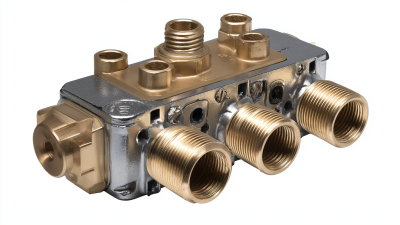

Pneumatic valves are integral components in industrial automation applications, playing critical roles in controlling the flow and direction of compressed air throughout a system. These valves enable precise control of pneumatic actuators, which are essential for executing repetitive tasks such as assembly, packaging, and material handling. By regulating air pressure and volume, pneumatic valves ensure that machines operate efficiently and safely, significantly reducing the risk of mechanical failure.

In addition to enhancing operational efficiency, pneumatic valves contribute to the flexibility of automation systems. They can be easily integrated into existing setups and adapted to meet the changing demands of production processes. This adaptability makes pneumatic valves invaluable in environments where rapid changes are commonplace, allowing manufacturers to optimize workflows without extensive downtime.

Moreover, advancements in valve technology, such as faster response times and improved seal design, have further increased their reliability and performance, underscoring their importance in modern industrial automation.

Pneumatic valves are essential components in modern automation systems, offering a range of benefits that enhance operational efficiency and reliability. One of the key advantages of using pneumatic valves is their ability to provide precise control of air pressure and flow within various applications. This precision makes them ideal for tasks such as clamping, lifting, and positioning, which require accurate movement and response times. By minimizing the risk of overpressurization and ensuring consistent operation, pneumatic valves contribute significantly to the overall productivity of an automated system.

Moreover, pneumatic valves are renowned for their durability and low maintenance requirements. Unlike their electrical counterparts, pneumatic systems are less susceptible to environmental factors such as dirt and moisture, making them suited for demanding industrial environments. Their simple design also allows for easy installation and integration into existing systems, reducing downtime during setup. The combination of reliability and ease of use makes pneumatic valves a vital component in streamlining processes and improving automation efficiencies across various sectors.

Pneumatic valves play a vital role in the functionality of modern automation systems, acting as the control points that regulate compressed air to drive various processes. There are several common types of pneumatic valves, each designed to fulfill specific functions, ensuring efficiency and precision in operations. One of the most widely used types is the solenoid valve, which utilizes an electromagnetic coil to open or close the flow of air automatically. This type is particularly beneficial in applications requiring fast actuation, such as robotic systems and assembly lines.

Another important type is the direction control valve, which manages the flow path of the compressed air to different outputs. These valves often come in configurations like 2/2 or 5/2, depending on the number of ports and positions they provide. This versatility allows for complex movements in actuators and cylinders, facilitating the execution of various tasks within the automation framework. Additionally, flow control valves regulate the speed of pneumatic actuators by controlling the flow rate of the air, ensuring smooth and controlled operation. Collectively, these pneumatic valves are essential for enhancing the performance and reliability of automated systems across multiple industries.

This chart illustrates the percentage importance of various types of pneumatic valves in modern automation systems. Directional control valves lead in importance, followed by pressure relief valves and flow control valves, indicating their critical roles in ensuring operational efficiency.

The implementation of pneumatic valve systems in modern automation presents several challenges that need to be addressed to maximize efficiency. One significant issue is the integration of pneumatic valves with existing electronic control systems. As companies increasingly adopt smart technology, there can be compatibility concerns between traditional pneumatic systems and modern automation software. This often necessitates the development of custom interfaces or the use of specialized controllers, which can increase costs and complicate the system design.

Another challenge lies in the maintenance and reliability of pneumatic valves. Over time, pneumatic systems can suffer from wear and tear, leading to operational inefficiencies or failures. To mitigate this, companies are investing in advanced predictive maintenance technologies that leverage IoT sensors and data analytics to monitor valve performance in real-time. By proactively addressing potential issues before they lead to system downtime, businesses can ensure smoother operations and enhance the overall effectiveness of their automation systems.

Accreditations

ISO 9001 Quality Management

HSE Management Compliant

Products and services comply with relevant Australian (AS) and international (ISO, etc.) Standards.

"*" indicates required fields