In the world of fluid control, choosing the right component can influence efficiency and precision. According to John Stevens, a leading expert in valve technology, “A needle valve offers unparalleled precision in flow regulation.” This statement encapsulates the advantage of needle valves in various applications.

Needle valves are designed for fine flow adjustments. Their ability to manage small volume changes is crucial in industries like chemical processing and water treatment. A simple twist can lead to significant variations in flow rates. The design features a slender opening, allowing for meticulous control.

Yet, not every application requires a needle valve. For some, the complexity may seem excessive. Users must consider their specific needs. While the benefits are clear, a careful assessment is needed to avoid misapplication. Embracing this technology means embracing attention to detail in every system.

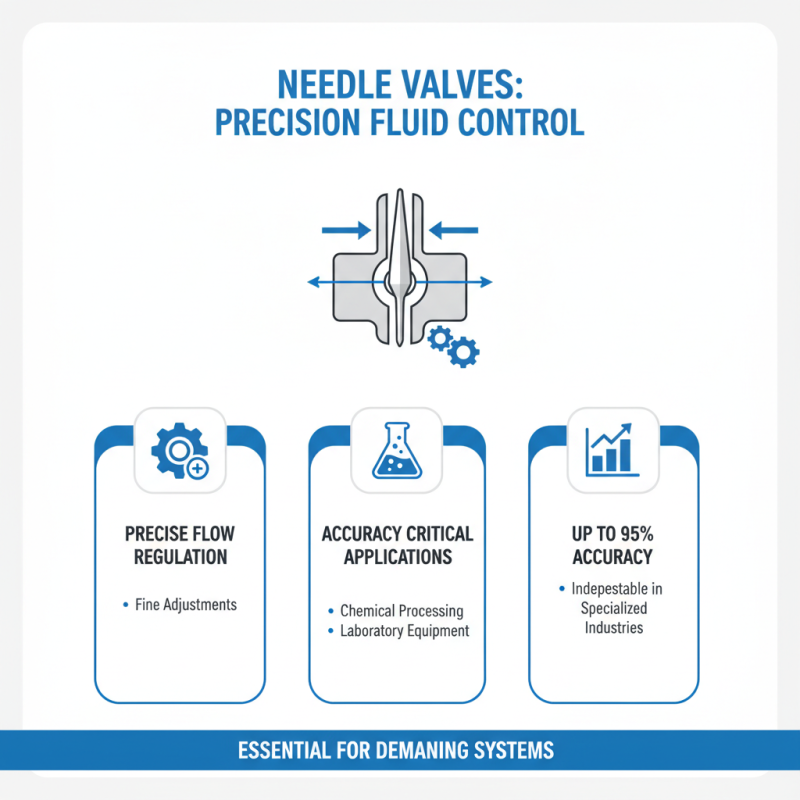

Needle valves are critical components in fluid control systems. They are designed for precise flow regulation, allowing for fine adjustments. This functionality is essential in applications that demand accuracy, such as in chemical processing and laboratory equipment. According to industry reports, needle valves can regulate flow rates with an accuracy of up to 95%, making them indispensable in specialized industries.

The design of a needle valve is what sets it apart. It features a conical disc and a unique threaded spindle. Together, these elements enable very small flow changes. Research indicates that the materials used in needle valve construction significantly affect their performance. For example, corrosion-resistant materials can increase lifespan and reliability. However, it's also essential to consider the trade-offs. Some materials may be less flexible, causing potential issues during installation or maintenance.

In complex systems, needle valves can be tricky. Users must be cautious; improper use can lead to flow disruptions. Reports suggest that nearly 20% of fluid control failures stem from valve malfunction. It's clear that while needle valves offer many advantages, they require careful handling. Making informed choices about their placement and installation can mitigate risks. Proper training and maintenance are crucial for optimal operation. This is an area that deserves reflection and ongoing improvement in practices across industries.

Needle valves are vital for precise fluid control in various systems. They provide fine adjustments to flow rates and pressure. This precision can be crucial, especially in applications like chemical processing and water treatment. According to industry reports, systems utilizing needle valves can achieve flow regulation accuracy within 5%, enhancing overall operational efficiency.

One key advantage is their compact size. They fit easily into tight spaces, which is beneficial for modern equipment that demands sleek designs. Additionally, needle valves have a simple construction. This simplicity allows for easier maintenance and troubleshooting. However, their narrow port design may lead to higher pressure drop. This aspect requires careful consideration in high-flow systems.

Furthermore, needle valves are known for their durability. Materials used in their construction withstand harsh environments. Reports indicate that systems with needle valves experience lower failure rates, often attributed to their robust design. Yet, users must remain aware of potential limitations. The need for precise adjustments can also lead to user error if not monitored closely. Balancing precision with operational demands remains a continuous challenge.

Needle valves are crucial in various industries. They offer precise flow control needed in applications requiring high accuracy. According to a recent report by Market Research Future, the global needle valve market is expected to grow at a CAGR of 5.6% by 2025. This growth shows their increasing importance in sectors like oil and gas, chemical processing, and water treatment.

In the oil and gas industry, needle valves ensure minimal pressure drop and secure throttling. They help manage flow rates in gas pipelines and refineries. Similarly, in chemical processing, these valves regulate fluid flows in reactors and control dangerous chemicals effectively. A study from Grand View Research highlights that the chemical sector is set to expand by 4.1% annually, indicating a steady demand for reliable flow control solutions.

Water treatment facilities also rely on needle valves to control the flow of fluids with precision. They contribute to maintaining optimal operational conditions in various stages of the treatment process. The Environmental Protection Agency (EPA) states that water contamination can impact millions. Hence, efficient fluid control is essential in safeguarding water quality. However, organizations must consistently evaluate their valve performance to prevent inefficiencies that may arise from wear and tear over time.

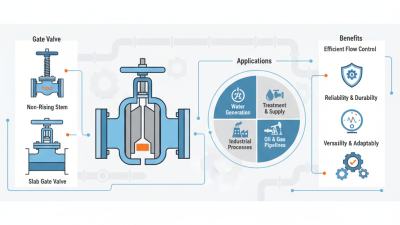

When considering fluid control, needle valves stand out for their precision. They differ significantly from ball valves or gate valves. Needle valves provide finer adjustments, making them ideal for applications requiring delicate flow regulation. This precision is necessary in systems where the flow must be managed carefully.

Ball valves, however, allow for quick on-off control. They function well in high-flow applications. Yet, they lack the fine control offered by needle valves. Similarly, gate valves excel in preventing backflow but don’t provide the nuanced adjustments needle valves do. Each valve type has strengths, but not all fit every need.

Choosing a valve type should involve consideration of the specific application. It’s not just about flow rates but also about control and responsiveness. Some might find needle valves more cumbersome for rapid flow changes. Reflecting on your requirements is crucial. There may be times when a simple ball valve suffices. The decision should be tailored to the task at hand.

When selecting a needle valve, it’s crucial to consider your specific fluid control needs. Needle valves are known for their precision in flow regulation. According to a report by the International Fluid Control Association, nearly 70% of industries require stringent flow control. This highlights the importance of choosing the right needle valve for your application.

Different fluids have varying viscosities. A needle valve that works well for water may not perform effectively with thicker fluids like oils or glycerin. The materials used in the valve body also affect compatibility and longevity. For example, stainless steel is often preferred for corrosive liquids. A study indicates that improper material selection leads to 25% of valve failures in critical applications.

Performance is not just about choosing the right material or design; it also depends on installation and maintenance. Misalignment during installation can cause issues like leaks or reduced efficiency. Regular inspections can prevent these problems, yet many neglect this step. The complexity of systems makes it easy to overlook details. Each decision impacts overall fluid management and safety.

Accreditations

ISO 9001 Quality Management

HSE Management Compliant

Products and services comply with relevant Australian (AS) and international (ISO, etc.) Standards.

"*" indicates required fields