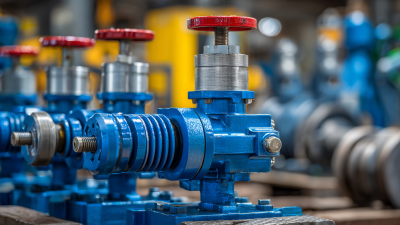

In the world of gas systems, ensuring that your gas valve operates at peak efficiency is crucial not only for performance but also for safety. A gas valve that is optimized can significantly reduce the risk of leaks and malfunctions, allowing for smooth operation in both residential and commercial applications.

Understanding the nuances of gas valve functionality and maintenance is essential for anyone who relies on gas for heating, cooking, or other applications. In this blog, we will explore five essential tips that will help you optimize your gas valve efficiency, enhancing both its performance and safety.

Whether you're a homeowner, a facility manager, or an industry professional, these actionable insights will provide you with the knowledge to make informed decisions about your gas valve maintenance and operations. Join us as we delve into practical strategies that can lead to a safer and more efficient gas utilization experience.

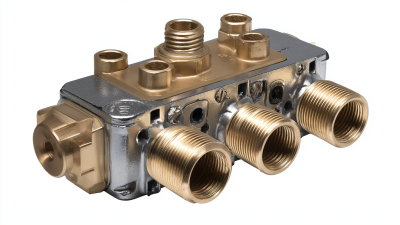

Understanding the key components of gas valves is crucial for optimizing their efficiency and enhancing safety in various industrial applications. Gas valves typically consist of essential parts such as the actuator, body, and trims, each playing a vital role in regulating the flow of gases. For instance, the actuator is responsible for opening and closing the valve in response to control signals, thereby maintaining appropriate pressure levels. According to industry reports, the global industrial valve market, which encompasses gas valves, is expected to witness significant growth, projected to reach USD 90 billion by 2025, driven by advancements in technology and increasing demand for safety protocols in gas handling.

Furthermore, efficient gas valve performance contributes not only to safety but also to energy conservation. Data indicates that optimizing valve configurations can reduce energy consumption by up to 30%, demonstrating the importance of proactive maintenance and system upgrades. Implementing regular checks and using materials designed to withstand varying pressures can enhance durability and function, thus ensuring that gas systems operate efficiently. In light of evolving regulations and environmental concerns, understanding and improving gas valve mechanics will be critical for industries looking to meet safety standards while also enhancing their overall operational performance.

This chart demonstrates the relationship between various aspects of gas valve maintenance and their impact on efficiency and safety performance. The data reflects optimal ranges for key maintenance components.

Regular maintenance is crucial for enhancing gas valve performance and ensuring safety in industrial applications. According to a report from the American Society of Mechanical Engineers (ASME), nearly 30% of industrial gas system failures are attributed to inadequate maintenance practices. Implementing a routine inspection schedule can significantly mitigate this risk, allowing for early detection of potential leaks or irregularities. This proactive approach not only extends the lifespan of gas valves but also improves their efficiency, reducing unnecessary energy costs.

Regular maintenance is crucial for enhancing gas valve performance and ensuring safety in industrial applications. According to a report from the American Society of Mechanical Engineers (ASME), nearly 30% of industrial gas system failures are attributed to inadequate maintenance practices. Implementing a routine inspection schedule can significantly mitigate this risk, allowing for early detection of potential leaks or irregularities. This proactive approach not only extends the lifespan of gas valves but also improves their efficiency, reducing unnecessary energy costs.

Additionally, the National Fire Protection Association (NFPA) emphasizes the importance of adhering to manufacturer guidelines for maintenance. Regular checks, including cleaning and replacing worn components, can prevent hazardous situations. Data from the US Department of Energy indicates that properly maintained gas systems operate at 15-20% higher efficiency, further illustrating the critical nature of these practices. By prioritizing regular maintenance, facilities can enhance both the performance and safety of their gas valves, leading to more reliable operations overall.

When it comes to ensuring safe and efficient operation of gas systems, recognizing the signs of inefficiency in your gas valve is crucial. One of the first indicators that something isn’t quite right is fluctuating pressure readings. If you notice inconsistent pressure levels, it could signify a malfunctioning valve that requires immediate inspection. Other physical signs may include gas leaks, which are often accompanied by a distinct smell. Any hint of leakage not only compromises performance but also poses a serious safety hazard.

Another telltale sign to watch out for is unusual noises coming from the valve. Rattling or hissing sounds can indicate internal wear or improper sealing, suggesting that it's time for a thorough checkup. Regular maintenance inspections can help you catch these issues early, preventing more significant damage and ensuring optimal performance. If you’re experiencing any of these symptoms, it’s essential to consult a professional to evaluate and service your gas valve promptly. Keeping an eye out for these warning signs can greatly enhance the safety and efficiency of your gas system.

When it comes to handling gas valves, safety should always be your top priority. Proper precautions not only ensure the well-being of individuals but also optimize the performance of your gas system. Before operating any gas valve, make sure to wear appropriate personal protective equipment (PPE), including gloves and safety goggles. This will protect you from potential leaks or hazardous exposure.

Another essential tip is to ensure that the area around the gas valves is well-ventilated. Stale air can lead to dangerous buildup of gas, which increases the risk of fire or explosion. Regularly check for leaks using a soap solution, as this simple method can help identify weak spots in the system. Remember to keep a fire extinguisher nearby and familiarize yourself with its use, reinforcing an environment of preparedness.

Lastly, consider instituting a routine maintenance schedule for your gas valves. Regular inspections and performance checks can help identify problems before they escalate. If any issues arise—such as irregular sounds or difficulties in operation—address them immediately. Proactive monitoring not only enhances the efficiency of your system but significantly increases safety for everyone involved.

When it comes to upgrading your gas valve, selecting the right model is crucial for optimal efficiency and performance. Not all gas valves are created equal; they come in various types and specifications suited for different applications. Start by assessing the specific needs of your system, including flow rate, pressure requirements, and compatibility with existing infrastructure. This will help narrow down your options and ensure that the new valve works seamlessly with your setup.

Additionally, consider the materials and technology used in the gas valve construction. Opt for models made from high-quality materials that can withstand the environmental conditions and chemicals they might encounter. Smart gas valves, equipped with advanced monitoring and control features, can significantly enhance efficiency and safety. Investing in the right model not only improves performance but also reduces the likelihood of failures and maintenance issues, fostering a safe and reliable gas system for your operations.

Accreditations

ISO 9001 Quality Management

HSE Management Compliant

Products and services comply with relevant Australian (AS) and international (ISO, etc.) Standards.

"*" indicates required fields