As we look towards 2025, the landscape of gas valves is set to experience significant technological advancements that will redefine the industry's standards and practices. With an increasing demand for energy efficiency and safety, manufacturers must innovate to meet the evolving needs of consumers globally. This blog will explore the latest trends in gas valve technology, emphasizing the importance of selecting reliable manufacturers, particularly from China, who are poised to become trusted global partners.

We will also delve into alternative types of gas valves that are gaining traction in the market, reflecting the shift towards more sustainable and efficient solutions. Join us as we uncover the future of gas valve technology and what it means for both manufacturers and end-users in a rapidly changing environment.

In the manufacturing industry, gas valves play a crucial role in ensuring safety, efficiency, and reliability. High-quality gas valves are essential components in various applications, from residential heating systems to large industrial processes. These valves control the flow of gas, preventing leaks and maintaining optimal pressure, which directly impacts the overall operation and safety of systems. Without reliable gas valves, manufacturers risk production downtime and safety hazards, making the choice of supplier and product quality paramount.

Investing in premium gas valves, particularly from trusted manufacturers like those in China, can significantly enhance operational performance. These manufacturers understand the rigorous standards required for gas valve production, adhering to international quality certifications and utilizing advanced technology in their processes. By prioritizing quality gas valves, manufacturers can benefit from reduced maintenance costs and prolonged service life, ultimately leading to higher productivity and profitability. As industries evolve and demand becomes more stringent, the importance of selecting the right partner for gas valve procurement cannot be overstated.

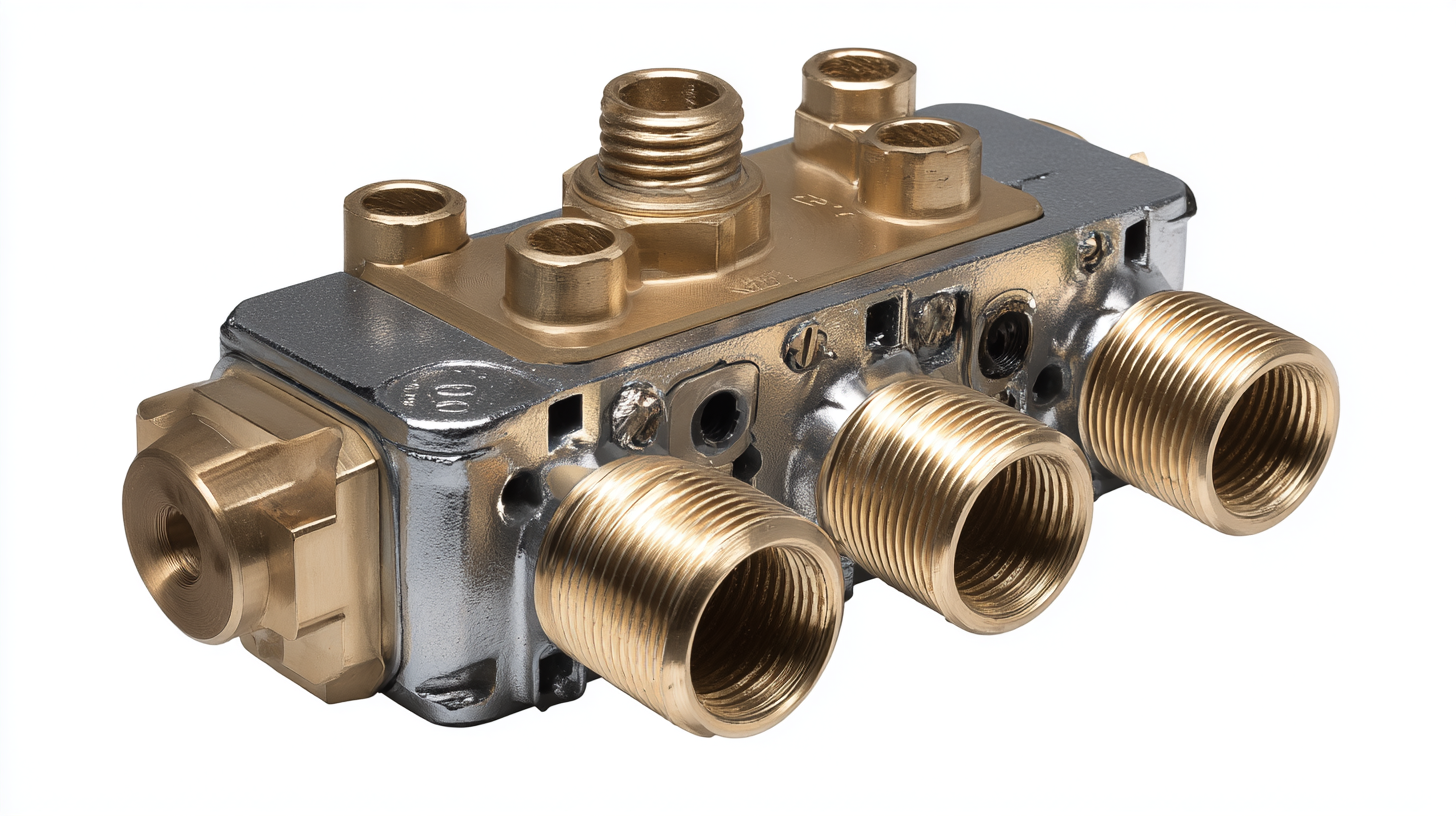

When selecting premier gas valves from China, several key features warrant careful consideration to ensure optimal performance and safety. First and foremost, look for valves constructed from high-quality materials, such as stainless steel or brass, which provide durability and corrosion resistance. These materials enhance the valve's lifespan, especially in environments exposed to harsh chemicals or extreme temperatures. Additionally, valves should conform to international safety standards, ensuring reliability and compliance with regulations.

Another crucial aspect is the valve's design and functionality. Opt for valves with precision engineering to guarantee smooth operation and minimal leakage. Features such as adjustable flow rates and easy installation can significantly enhance usability, making maintenance straightforward. Furthermore, consider valves equipped with advanced sealing technologies to prevent gas leaks, which is paramount for both safety and efficiency. By focusing on these essential characteristics, companies can partner with reputable Chinese manufacturers to secure gas valves that meet their operational needs and uphold high safety standards.

| Feature | Description | Importance |

|---|---|---|

| Material Quality | High-grade materials ensure durability and safety. | Critical for longevity and performance. |

| Design Standards | Compliance with international design standards for functionality. | Essential for operational efficiency. |

| Testing and Certification | Products must undergo rigorous testing to meet certification requirements. | Ensures safety and reliability in usage. |

| Customization Options | Availability of custom designs for specific applications. | Important for meeting unique client needs. |

| Supplier Reputation | Track record of reliability and quality in manufacturing. | Critical for establishing trust and partnership. |

| Cost-Effectiveness | Competitive pricing without compromising quality. | Key for budget management in procurement. |

Choosing the right gas valve for your specific applications can greatly influence the efficiency and safety of your operations. Begin by assessing the type of gas you will be using, as different gases have unique properties that may require specific valve materials and designs. For instance, natural gas, propane, and industrial gases all have varying levels of pressure and corrosiveness that can impact valve performance. Understanding these fundamentals will guide you in selecting a valve that can withstand your operational demands.

Next, consider the application conditions, such as pressure ratings, temperature ranges, and flow requirements. Valves are categorized by their operational capabilities, and choosing the right one involves ensuring it fits within these parameters. A properly rated valve not only enhances functionality but also reduces the risk of failures or accidents. Additionally, factor in installation and maintenance ease, as these aspects can significantly impact long-term operational costs. With the right information at hand, partnering with a manufacturer like Premier Gas Valves can streamline your selection process, helping you secure a reliable solution tailored to your needs.

When it comes to sourcing gas valves, partnering with a trusted global manufacturer can bring significant advantages. One key benefit is the assurance of

quality control throughout the manufacturing process. Reputable manufacturers adhere to

international standards and regulations, ensuring that their products are reliable and safe for use in various applications. By choosing a manufacturer that

prioritizes quality, businesses can reduce the risk of product failure and enhance their operational efficiency.

Tip: Always request certifications and compliance documents from your manufacturer. This can help ensure that the gas valves meet

the necessary safety standards and regulations required in your industry.

Another advantage of partnering with a global manufacturer is the access to advanced technology and innovation. These manufacturers often invest in

research and development, leading to cutting-edge products that can improve performance and efficiency.

By collaborating with a forward-thinking partner, businesses can stay ahead of industry trends and incorporate the latest technologies

into their operations.

Tip: Look for manufacturers that offer customized solutions to meet your specific needs. This flexibility can lead to better-suited products that cater to unique operational requirements,

ultimately resulting in improved performance and customer satisfaction.

When it comes to maintaining and troubleshooting gas valves, a proactive approach is essential for optimal performance. Regular inspections can help identify potential issues before they escalate. Look for signs of wear or damage, such as cracked housings or loose fittings, and ensure all connections are tight. Keeping the valve body clean from debris and corrosion will also extend its lifespan and improve functionality.

Tip: Always refer to the manufacturer's guidelines for specific maintenance procedures and intervals. This ensures you are following the correct protocol designed for your specific gas valve model, enhancing reliability and safety.

In case of malfunction, startups that are hesitant or uneven can often signal an internal problem. A thorough inspection should be conducted, checking for blockages or obstructions in the valve’s pathway. Additionally, listen for any unusual noises during operation, as these can indicate internal wear or failure.

Tip: Establish a troubleshooting checklist to streamline the identification of common issues. This practice not only saves time but also provides a clear framework to resolve problems effectively and maintain performance.

Accreditations

ISO 9001 Quality Management

HSE Management Compliant

Products and services comply with relevant Australian (AS) and international (ISO, etc.) Standards.

"*" indicates required fields