In the contemporary landscape of pneumatic systems, the role of air valves has become increasingly vital for ensuring operational efficiency and system reliability. According to a report by the International Pneumatic Equipment Manufacturing Association (IPEMA), the global pneumatic systems market is projected to reach USD 36 billion by 2025, with air valves being a key component in optimizing performance. These devices manage the flow and pressure of air within systems, directly influencing response times and energy consumption. Research indicates that incorporating high-quality air valves can reduce energy use by up to 15%, underscoring their importance in system design. As industries continue to seek automation and efficiency, understanding the intricate functions of air valves will be paramount in advancing pneumatic technology and enhancing overall productivity.

Air valves play a critical role in enhancing the efficiency of modern pneumatic systems. As essential components, they regulate the flow and pressure of air within the system, preventing backflow and ensuring optimal operation. By controlling the release and intake of air, these valves minimize energy wastage, which is crucial for improving overall system performance. Efficient air management can lead to significant energy savings, thereby reducing operational costs for industries reliant on pneumatic technology.

Moreover, the importance of air valves extends to ensuring the longevity of equipment. Proper flow regulation helps maintain consistent pressure levels, reducing wear and tear on machinery. This reliability not only enhances productivity but also minimizes maintenance needs, allowing for smoother operations and less downtime. Therefore, investing in high-quality air valves translates to long-term benefits for businesses by fostering efficient processes and extending the service life of pneumatic systems.

Air valves play a critical role in modern pneumatic systems by preventing pressure loss and enhancing overall system reliability. These valves function by regulating the flow of air within the system, ensuring that pressure is maintained at optimal levels. When the pneumatic system operates, fluctuations in pressure can occur due to changes in load or environmental conditions. Air valves respond to these changes by opening or closing as necessary, which mitigates the risk of excessive pressure drops that could compromise the system's efficiency.

Furthermore, the presence of air valves contributes to better energy management within pneumatic systems. By controlling air flow effectively, these valves reduce the need for compressors to work harder, thus conserving energy and lowering operational costs. Additionally, improved pressure stability minimizes wear and tear on system components, which can lead to longer equipment life and less frequent maintenance. Overall, air valves are essential for ensuring that pneumatic systems operate smoothly and reliably, supporting the demands of various industrial applications.

Air valves play a crucial role in modern pneumatic systems, managing airflow and pressure to ensure efficiency and safety. There are several types of air valves, each designed for specific functions tailored to the needs of various applications. For instance, the pressure relief valve allows excess pressure to escape, protecting equipment from potential damage. According to a report by the International Society of Automation, around 30% of pneumatic system failures are attributed to pressure imbalances, highlighting the importance of such valves in maintaining system integrity.

Another key type of air valve is the solenoid valve, which controls the direction of airflow based on electrical signals. This can significantly enhance response times and precision in automated systems. A study published by the Fluid Power Journal indicates that implementing solenoid valves can improve system efficiency by up to 25%, representing a substantial advantage in high-demand environments. Additionally, flow control valves regulate the speed of actuators, thus optimizing performance in applications ranging from manufacturing to transportation. Understanding these diverse valve types and their specific functions is vital for engineers and technicians aiming to enhance the reliability and efficiency of pneumatic systems.

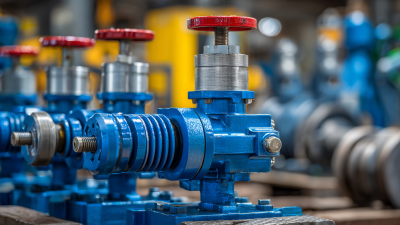

In modern industrial applications, air valves play a crucial role in the efficient functioning of pneumatic systems. These components are essential for regulating the flow of compressed air, thereby ensuring that various machinery operates smoothly. One common application of air valves is in automated assembly lines, where they control the movement of actuators that perform repetitive tasks with precision. By accurately managing air pressure, these valves facilitate the swift and reliable operation of tools and devices, enhancing productivity and safety in manufacturing environments.

Another significant application of air valves can be found in HVAC systems, where they regulate airflow and maintain proper pressure levels. In buildings, these valves ensure that heating, ventilation, and air conditioning operate effectively, contributing to energy efficiency and occupant comfort. Additionally, air valves are critical in the transportation sector, particularly in braking systems for vehicles and trains. They provide the necessary control over air pressure, allowing for quick and reliable braking, which is vital for safety. Thus, the versatility and importance of air valves in various industrial settings cannot be overstated, as they are integral to optimizing performance and reliability in pneumatic systems.

Air valves play a critical role in the functionality and efficiency of modern pneumatic systems. To ensure these systems operate smoothly, regular troubleshooting and maintenance of air valves are essential. One common issue is leakage, which can lead to pressure loss and reduced performance. To identify leaks, inspect the valve seals and connections for signs of wear or damage. Applying soapy water on suspected areas can help detect escaping air bubbles, indicating where repair or replacement is necessary.

Another frequent challenge is the accumulation of contaminants, which can hinder the operation of air valves. Periodic cleaning is vital; users should remove any debris or particulate build-up that may affect the valve's performance. Additionally, checking the actuator's response during operation can provide insights into the valve’s condition. If the valve is sluggish or unresponsive, it may require lubrication or, in more severe cases, a complete overhaul. By following these troubleshooting and maintenance tips, operators can extend the lifespan of air valves and ensure optimal performance in pneumatic systems.

Accreditations

ISO 9001 Quality Management

HSE Management Compliant

Products and services comply with relevant Australian (AS) and international (ISO, etc.) Standards.

"*" indicates required fields