When it comes to water management, understanding water valves is essential. Experts agree that knowing the various types of water valves can enhance efficiency. Charles Henderson, a noted specialist in fluid dynamics, states, "Selecting the right water valve is crucial for any plumbing system." His insight reflects the intricate world of water valves.

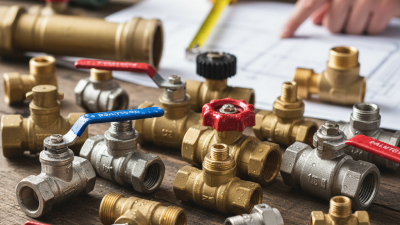

Water valves come in numerous types, each suited for different applications. From gate valves to ball valves, each valve has unique functions. A proper understanding helps avoid leaks and inefficiencies. Many may overlook this aspect, leading to costly repairs and water wastage.

Yet, despite their importance, misconceptions about water valves persist. Some people think all valves serve the same purpose. This belief can result in choosing the wrong type. It's imperative to educate oneself about various options to make informed decisions.

Water valves play a crucial role in managing the flow of water in various systems. They regulate water pressure and direct the flow in plumbing, irrigation, and industrial applications. Understanding how these valves work is vital for both professionals and DIY enthusiasts. The right valve can prevent leaks and conserve water, while the wrong choice may lead to inefficiencies.

Different types of valves serve specific purposes. For instance, gate valves are used for on/off control. They offer minimal flow restriction but can be slow to operate. On the other hand, ball valves provide quick shut-off and are often preferred in residential applications. There are also check valves, which allow flow in one direction, preventing backflow. Each type has its advantages and disadvantages, which should be considered carefully when selecting the appropriate valve for a project.

Valves, while simple in design, can be complex in their operation. A small error in installation can lead to significant issues. Rainwater harvesting systems or irrigation setups often depend on reliable valves. If they fail, the entire system can be compromised. Reflecting on these aspects can help in making informed choices and ensuring efficiency in water management.

Understanding the various types of water valves is essential for plumbing, irrigation, and industrial applications. Here is a visual representation of the most common types of water valves and their usage frequency.

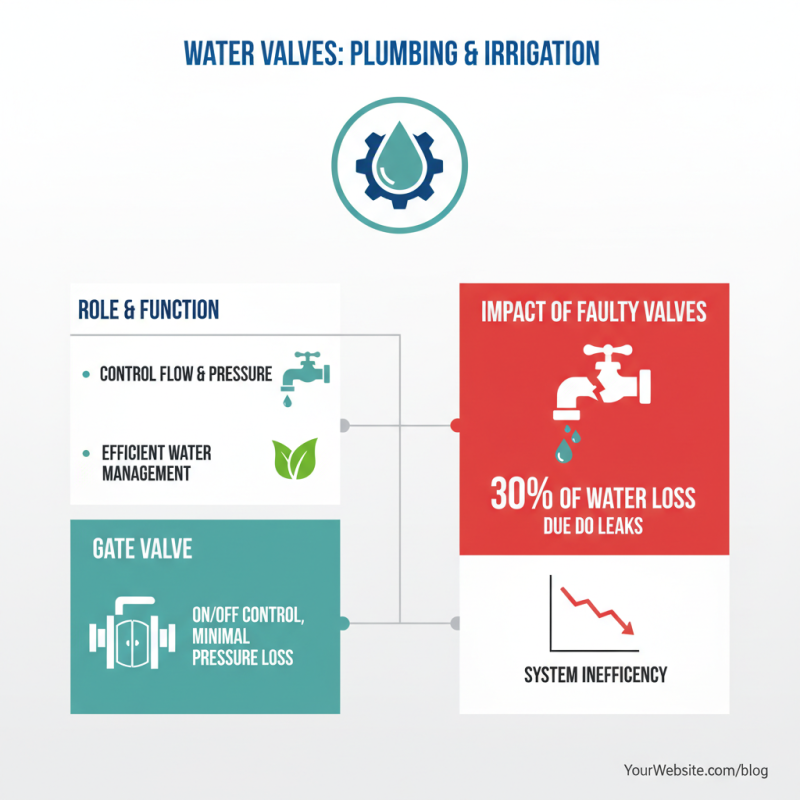

Water valves play a crucial role in plumbing and irrigation systems. They control flow and pressure, ensuring efficient water management. Each type of valve serves specific functions. For instance, the gate valve is designed for on/off control. It provides minimal pressure loss. According to industry reports, about 30% of water loss in systems is due to leaks from faulty valves.

Ball valves are another important type. They offer low resistance and quick operation. Their design allows for a tight seal, minimizing leakage. Studies show that improper valve selection can increase maintenance costs by up to 25%. This highlights the importance of understanding valve functions.

Another common type is the check valve, which prevents backflow. Backflow can contaminate water supplies. Research indicates that 80% of water contamination issues could be avoided with proper valve usage. Each type of valve has unique characteristics. Knowing these can significantly enhance system performance. However, improper installations still happen frequently, creating potential hazards. The right choice of valve depends on the specific application. Understanding these key features can lead to better water management strategies.

When managing water systems, understanding the various types of water valves is crucial. These components control water flow efficiently. There are ten primary types of water valves, each serving a unique purpose.

Gate valves are often used for on/off control. They provide minimal flow resistance. However, they are not ideal for throttling. Globe valves, on the other hand, are better for regulating flow. They can be a bit tricky to maintain, which may lead to leakage over time.

Another important type is the ball valve. It offers a quick shut-off. According to industry reports, ball valves have a failure rate of about 2% when properly installed. This reliability makes them a preferred choice for many applications.

Tips: Remember to consider valve material and pressure ratings. They play a key role in long-term durability. Regular maintenance is essential to prevent issues. It’s easy to overlook minor leaks, but even small drips can lead to significant waste.

Check valves prevent backflow, ensuring water moves in the desired direction. However, they may become jammed with debris. Regular inspection is critical to avoid unexpected failures. Each type of valve has its strengths and weaknesses. Understanding these can save you time and money in the long run.

Water valves are essential components in various applications, impacting efficiency and control. Different types serve specific functions. For instance, gate valves are ideal for on/off control in large pipelines. They are often used in municipal water systems. Their design ensures minimal pressure loss, making them efficient in high-flow situations. However, they can be slow to operate, which might not be ideal in urgent scenarios.

When it comes to maintaining water valves, routine inspection is key. A study from the American Water Works Association revealed that routine maintenance can extend valve life by up to 30%. Regular checks for leaks and wear can significantly reduce costly repairs. Ignoring minor issues can lead to bigger problems down the line.

Cleaning valves regularly is essential for optimal performance. Dirt can clog mechanisms, affecting flow rates and efficiency. Research shows that failing to clean valves can reduce their lifespan by as much as 50%. Use a gentle cleaning agent and check for any corrosion. Corroded valves not only fail faster but can introduce contaminants into the system.

Lubrication of moving parts is another critical aspect. Proper lubrication prevents friction, allowing for smooth operation. However, over-lubrication can lead to its own set of problems. Oil buildup can attract dirt, causing blockages. Keeping a balance is important for valve health. These maintenance practices involve some trial and error. It's essential to adapt strategies based on your specific systems and usage.

Accreditations

ISO 9001 Quality Management

HSE Management Compliant

Products and services comply with relevant Australian (AS) and international (ISO, etc.) Standards.

"*" indicates required fields