In the ever-evolving landscape of industrial automation, control valves remain a cornerstone of operational efficiency and process optimization. As we delve into the top 10 control valves for 2023, it's essential to recognize the voice of industry experts who constantly drive innovation in this field. Among them, Dr. Emily Chen, a renowned expert in process engineering, emphasizes, "The right control valve can dramatically influence system performance, ensuring that processes are not only efficient but also reliable."

This statement underscores the critical role that control valves play in various applications, from chemical processing to water treatment. With advances in technology and materials, today's control valves are designed to offer enhanced precision and durability, allowing industries to operate at peak performance levels. As we outline the top contenders for this year, we will explore the distinct features that make these control valves not just components, but vital instruments for achieving excellence in operational processes.

Ultimately, selecting the right control valve is more than a matter of functionality; it is a strategic decision that impacts the overall success of manufacturing and production systems. By investing in high-performing control valves, companies can foster greater efficiency and reliability, paving the way for sustainable growth in an increasingly competitive environment.

Control valves play a critical role in various industrial applications by regulating the flow, pressure, and temperature of fluids within systems. These valves ensure that processes operate efficiently and safely, ultimately enhancing the overall productivity of manufacturing and processing industries. The importance of control valves cannot be overstated, as they contribute significantly to maintaining desired operational parameters, optimizing energy usage, and protecting equipment from damage due to overpressure or flow anomalies.

In sectors such as chemical processing, oil and gas, and water treatment, control valves are vital for adapting to changing conditions and maintaining system reliability. They allow for precise adjustments and control over fluid dynamics, which is essential for achieving optimal performance. By incorporating advanced technologies and materials, modern control valves provide improved responsiveness and resilience, enabling industries to meet their increasingly complex operational demands while minimizing downtime and maintenance costs. The ongoing evolution of control valve technology reflects the industry's commitment to achieving higher levels of efficiency and performance.

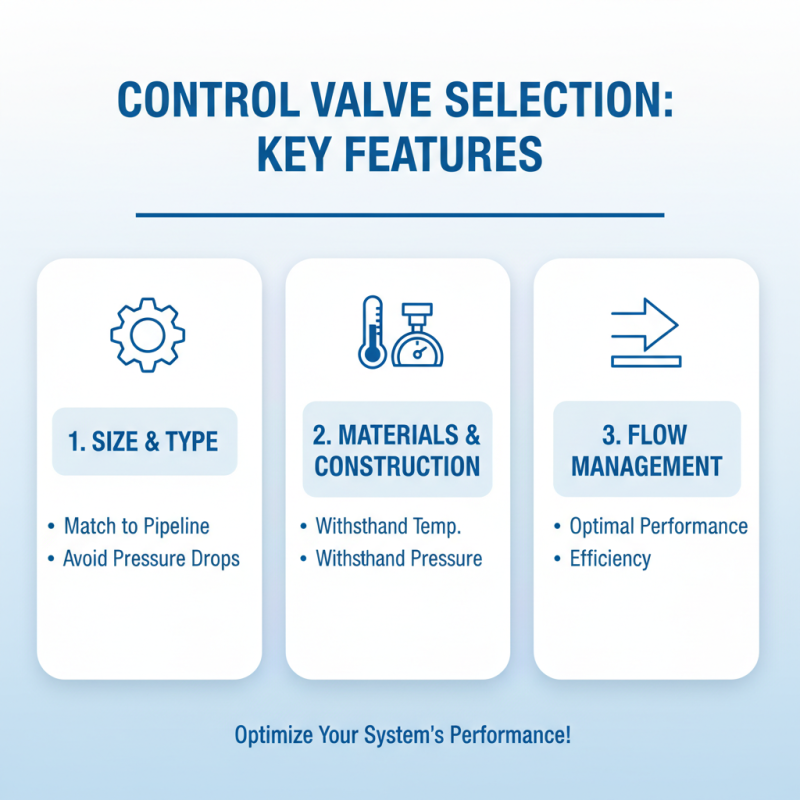

When selecting control valves for optimal performance and efficiency, several key features should be considered. First, the valve size and type play a critical role in ensuring proper flow management. Match the valve size to the pipeline specifications to avoid pressure drops and inefficiencies. Additionally, consider the valve's materials and construction, as they must withstand the operating conditions of the specific application, including temperature and pressure levels.

Another essential factor is the valve's response time and control accuracy. Opt for valves equipped with precise positioning systems that can easily adapt to changing flow conditions. This responsiveness enhances process stability and reduces energy consumption. Furthermore, evaluate the availability of advanced control options, such as digital actuators and integrated monitoring tools, which can provide real-time data and diagnostics. These features not only facilitate proactive maintenance but also contribute to improved energy savings and operational efficiency throughout the valve's lifecycle.

In 2023, the efficiency and reliability of control valves play a crucial role in various industries, influencing overall system performance and operational costs. When analyzing the top control valves, key metrics such as response time, pressure drop, and flow characteristics emerge as essential factors. Advanced design features, such as precision actuation and intelligent automation, enhance reliability, allowing these valves to maintain optimal performance under varying conditions.

The importance of material selection cannot be overstated, as it directly impacts durability and maintenance requirements. Control valves made from corrosion-resistant alloys and high-performance polymers extend service life in challenging environments, ultimately reducing the frequency and cost of replacements.

As industries continue to seek greater sustainability, the integration of smart technologies for real-time monitoring and diagnostics is increasingly common, offering insights that can prevent failures and optimize functionality. This focus on both performance and reliability confirms that the right control valve can significantly improve operational efficiency in 2023 and beyond.

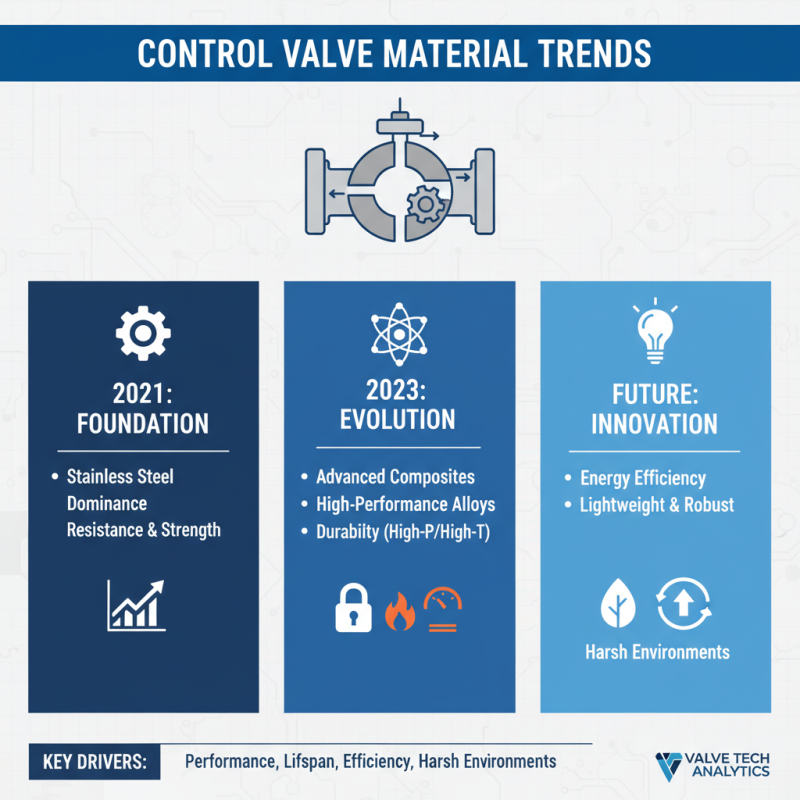

The selection of material types in control valve design is critical for ensuring optimal performance and efficiency. According to the 2021 Control Valve Market Research Report, the material composition of control valves significantly affects their operational lifespan and efficiency, with stainless steel being favored for its corrosion resistance and mechanical strength. In 2023, the trend continues towards high-performance materials including advanced composites and alloys, which provide enhanced durability under high-pressure and high-temperature conditions. The increasing need for energy-efficient systems further drives innovation in material science, promoting the development of lightweight yet robust materials that can withstand harsh environments.

A comparative analysis of material types reveals distinct advantages and limitations. For instance, while PVC control valves are often more affordable and suitable for non-corrosive fluids, they cannot match the temperature and pressure ratings of metal valves. Data from industry standards indicate that metal valves typically boast a pressure rating of up to 300 psi or more, whereas PVC valves generally cap around 150 psi. As industries push for sustainability, the shift towards eco-friendly materials, such as bio-based composites, is gaining traction. Reports project a growth rate of approximately 8% in the adoption of sustainable materials in control valves by 2025, reflecting a broader trend toward environmentally-conscious engineering practices across various sectors.

The landscape of control valve technology is continuously evolving, driven by advancements in materials science, automation, and data analytics. In 2023, the integration of smart technologies into control valves is paramount, allowing for real-time monitoring and adjustments that enhance both performance and efficiency. These smart valves are equipped with advanced sensors that provide crucial data on flow rates, pressure, and temperature, enabling operators to make informed decisions and respond swiftly to changes in operational conditions.

Furthermore, sustainability is shaping future trends in control valve design. Increased emphasis on energy efficiency and reduced emissions is prompting manufacturers to innovate. Newer materials and designs not only improve durability but also contribute to lower lifecycle costs and minimal environmental impact. As industries focus on sustainable practices, control valves that optimize energy use and reduce waste will play a critical role in achieving overall operational efficiency. The convergence of these technological trends is set to redefine the performance benchmarks for control valves in the coming years, ensuring that they meet the demands of modern industrial applications.

Accreditations

ISO 9001 Quality Management

HSE Management Compliant

Products and services comply with relevant Australian (AS) and international (ISO, etc.) Standards.

"*" indicates required fields